Vibration finishing is a polishing technique that creates a swirling pattern on a stainless steel surface.This polishing technique is used for a variety of products, and is especially popular for building materials today.

|

Brand:

|

|

|

Place Of Origin:

|

|

|

Payment Terms:

|

|

|

Delivery Time:

|

|

|

Package Detail :

|

|

|

Price Term:

|

|

|

Sample:

|

|

|

Item |

ODM Yellow Rose Color Design 304 316 Grade Stainless Steel Sheet By Vibraion Process Finishing | |

| Standard | ASTM, AISI, DIN, EN, GB, JIS | |

|

Brand Name |

Grand Metal |

|

|

Type |

Sheet or Coil |

|

|

Grade |

304 316 |

|

|

Material |

Stainless Steel |

|

|

Thickness(mm) |

0.3mm-3mm |

|

|

Size(mm) |

Main Size |

Other Size |

| 1219mmx2438mm | Customized | |

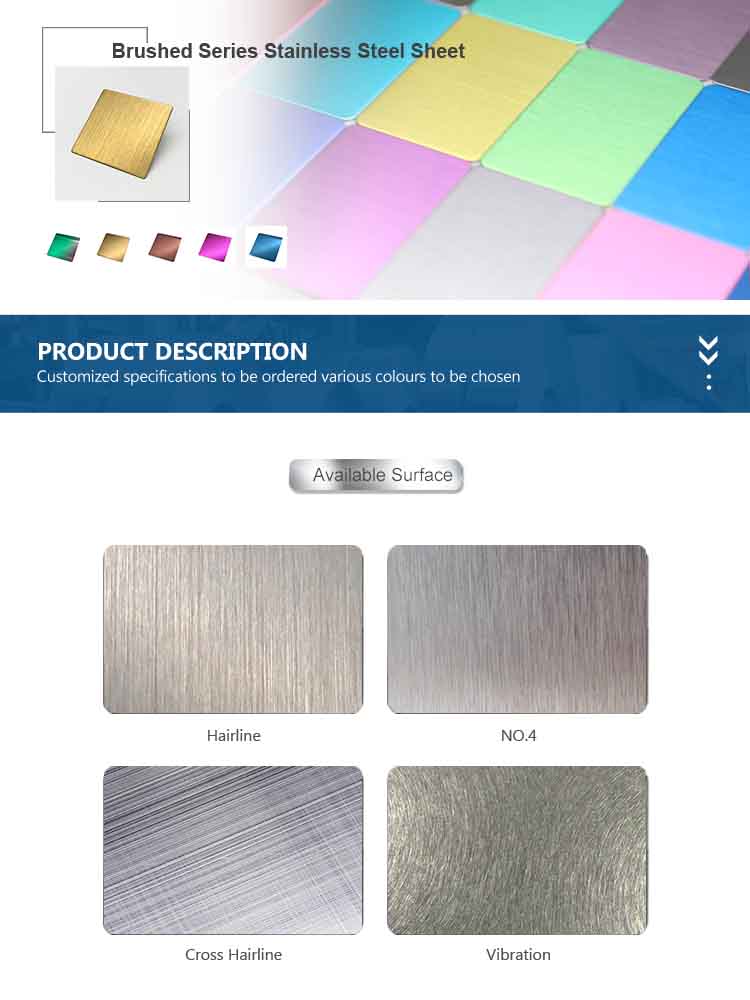

| Surface Finish | No.4,Satin,Brush,#4,N4 | |

| Color | Titanium gold,rose gold,champagne,gold | |

| Coffee,brown,bronze,brass,wine red,purple | ||

| Sapphire,Ti-black,wooden,marble,texture,etc. | ||

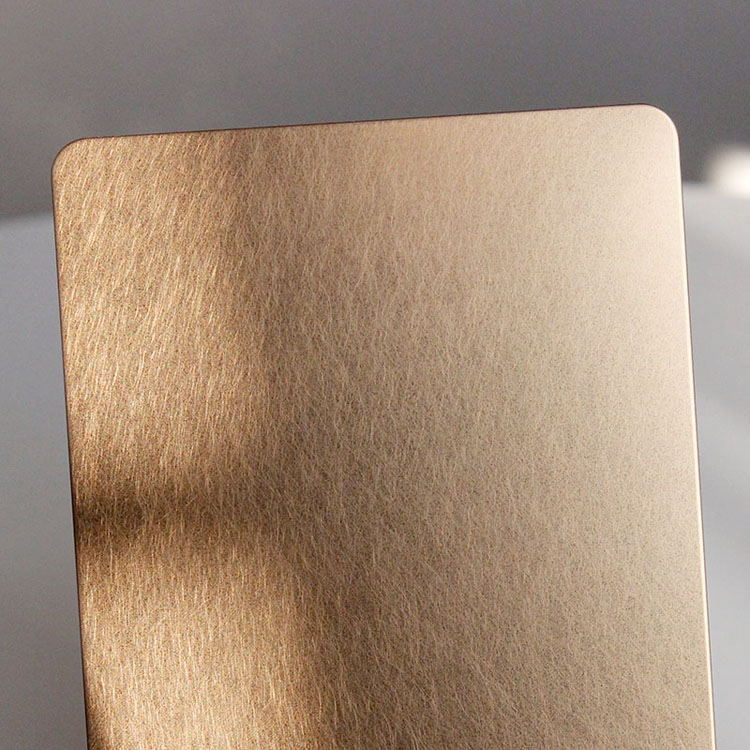

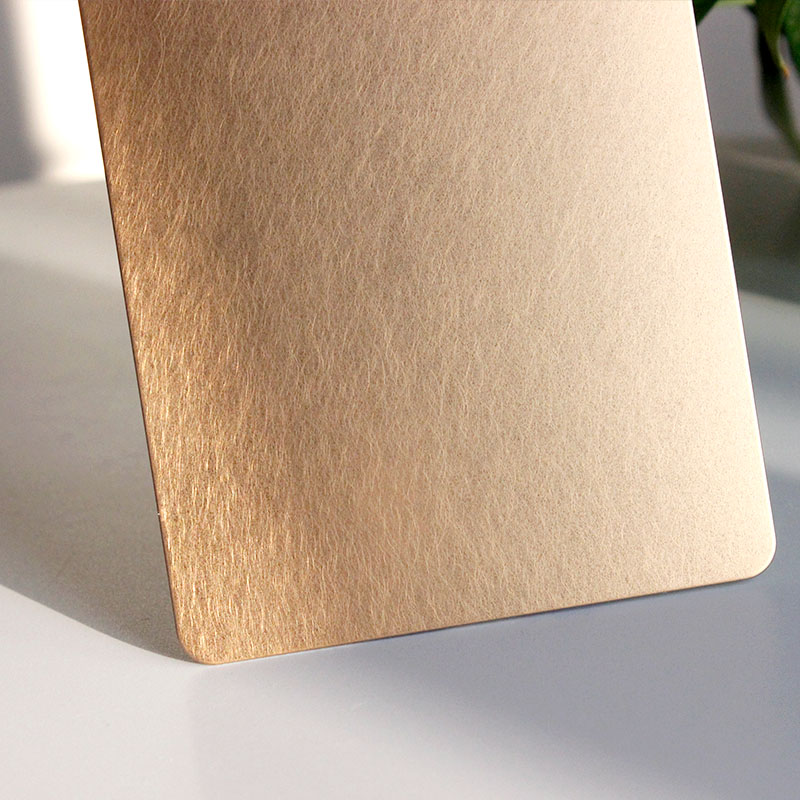

What is Vibration Finish Stinless Steel Sheet?

Vibratory finishing is a polishing technique that creates a swirling pattern on a stainless steel surface.

This polishing technique is used for a variety of products, and is especially popular for building materials today.

The features of Vibration stainless steel sheet:

Vibration is a multi-directional finish. It is also known by the names Non-Directional Satin and Angel Hair. Vibration has a uniform texture with random, multi-directional grit lines. To ensure the highest degree of consistency, this brushed steel is inspected to a visual standard.

Vibration has a uniform texture with random, multi-directional grit lines with highest degree of consistency, which was also known by the names Non-directional Satin and Angel Hair.

Vibration is becoming one of the most popular surface finishes because of its non-direction and high-density scratch reacting in creditable fine texture.

Why choose our Vibration finish stainless steel sheet:

| Advantage | 1、Fireproof,Waterproof,Corrosion. |

| 2、Protection,Colorful,Fashionable,Delicate,Luxurious,Fast Color,Stable. | |

| 3、In Decorative Effection. |

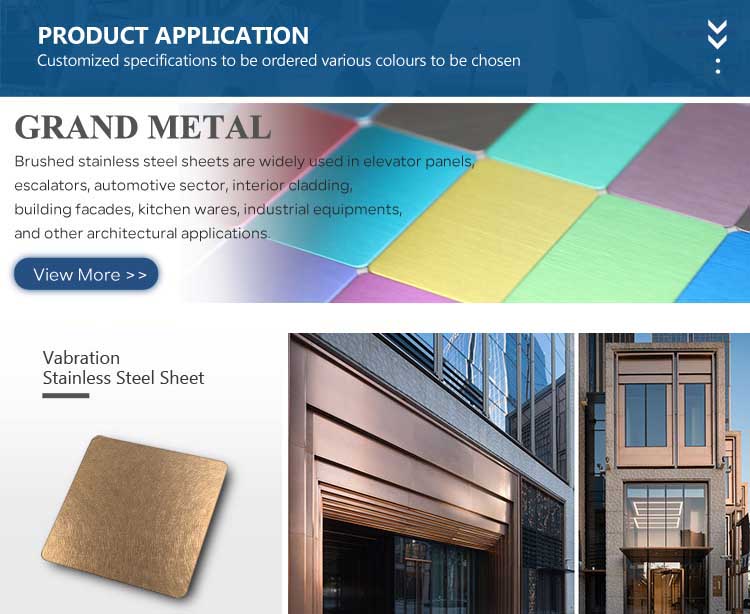

Grand Metal’s vibration finish sheet is characterized by fine polishing grit lines that are uniform and directional in appearance.

A durable paint with a smooth, velvety gloss texture.

What Service On Can We Provide For You ?

1、Surface Finish Service

We also provide the scope of product customized service which including surface parameter customization,color customization,pattern customization,size and thickness customization,etc. The specific processing technology includes mirror surface.frosting,etching,sandblasting,embossing,stamping,color oil,copper plating,laser,shearing,folding planing,PVD color coating and other common processes etc.

2、Anti-finger Print Finish Service

We using an environmentally friendly metal surface treament method,the solvent-based solution is coated on the metal surface to form a layer based on the non-polar nano hybrid coating,which can not only achieve the effect of anti-fingerprint and easy cleaning,but also improve the corrosion resistance and friction resistance of the plate,causing the coating. The surface is more strengthened,which in turn makes the color of substrate more saturated and less prone to discoloration.

3、Anti-Scratch Finish Service

According to your needs, we will apply a layer of coating with excellent hardness and wear resistance on the surface of the stainless steel plate using special coating technology. This coating is usually a high molecular polymer material, such as polyurethane, acrylate, etc., which has high scratch resistance and wear resistance.

In kitchens and countertops, stainless steel is often given a mirror finish in order to make it look nicer. However, the vibratory finish is a finish that adds patterns to the surface, giving the design a three-dimensional feel.

As a result, it has the effect of making scratches less noticeable, and is often used for stainless steel in elevators.

However, since scratches are more noticeable with a thinly polished stainless steel vibration finish, we recommend a stainless steel vibration finish with a deeper polish than a standard vibration finish when purchasing products.

| Application | 1.Indoor and outdoor public space backdrop |

| 2.Aisle | |

| 3.Entrance background image of the wall | |

| 4.Door signs | |

| 5.Ceiling | |

| 6.Living room background wall | |

| 7.Elevator cabin,handrail | |

| 8.Kitchen equipment | |

| 9.Specially for bar,club,KTV,hotel,bath center,villa. |

|

Protective Film |

1. Double layer or single layer. 2. Black and white PE film/Laser (POLI) film. |

|

Packing Details |

1. Wrap with waterproof paper. 2. Cardboard encase all packs of the sheet. 3. The strap aligned with edge protection. |

|

Packing Case |

Strong wooden case, metal pallet and customized pallet are acceptable. |

Q1:Can I combine different colors or finishes of stainless steel sheets in my design?

A1:Yes, you can combine different colors or finishes of stainless steel sheets to create unique and custom designs. Mixing colors or finishes can add visual contrast and enhance the overall aesthetic appeal of your project.

Q2:How do I repair scratches or damage on colored stainless steel sheets?

A2:Repairing scratches or damage on colored stainless steel sheets may require professional assistance. Depending on the extent of the damage, techniques such as color blending, touch-up paints, or refinishing may be used to restore the appearance of the sheet.

Q3:Are colored stainless steel sheets prone to fading?

A3:Colored stainless steel sheets are designed to be fade-resistant. The coloring processes used, such as PVD coating, create a strong bond between the color and the stainless steel substrate, ensuring long-lasting color retention even in outdoor or high-UV exposure applications.

Q4:Are colored stainless steel sheets more expensive than regular stainless steel sheets?

A4:Colored stainless steel sheets may have a higher cost compared to regular stainless steel sheets due to the additional processes involved in coloring them. The specific price difference can vary depending on factors such as color, finish, grade, and customization.

If you want to know more product information, or the latest quotation, you can contact us at any time, we will do our best to provide more services.

By continuing to use the site you agree to our privacy policy Terms and Conditions.