Stainless steel strip is a custom-width(Usually<600mm), continuous narrow strip of stainless steel, produced by precision longitudinal cutting of a wider master coil.Its surface finish can be 2B,2D,2E,BA,HL,No.4, No.8,with the steel grade 201/202/304/304l/316/316l/409/410/420/430/439 etc.

Request A Quotation

Stainless steel strips have relatively high tensile strength and impact resistance. This gives them strong structural support in a variety of applications.

Stainless steel strip contains a high proportion of chromium, forming a layer of dense chromium oxide film to prevent oxygen and water from contacting the stainless steel, thus providing strong corrosion resistance.

Stainless steel strip is stable over a wide temperature range. They can work in low and high temperature conditions.

Stainless steel strip can be precision cut, punched, bent, welded and machined into various shapes and sizes.

A smooth, reflective cold-rolled annealed and pickled finish produced by imparting a final light cold-rolled pass using polished rolls.

LEARN MORE

BA is called Bright Annealed, a specific bright surface finish which is produces by the mills for cold-rolled stainless steels.

LEARN MORE

The hairline finish is a design finish in which the surface of the metal has a straight line of hair.

LEARN MORE

A moderately rough and dull surface, ensuring that the stainless steel will meet mechanical property requirements.

LEARN MORE| Item | EN | AISI | JIS | ASTM |

|---|---|---|---|---|

| 1 | 1.4372 | 201 | SUS201 | / |

| 2 | 1.4373 | 202 | SUS202 | / |

| 3 | 1.4301 | 304 | SUS304 | S30400 |

| 4 | 1.4307 | 304L | SUS304L | S30403 |

| 5 | 1.4404 | 316L | SUS316L | S31603 |

| 6 | 1.4541 | 321 | SUS321 | S32100 |

| 7 | 1.4512 | 409L | SUS409L | / |

| 8 | 1.4000 | 410S | SUS410S | S41008 |

| 9 | 1.4031 | 420J2 | SUS420J2 | / |

| 10 | 1.4016 | 430 | SUS430 | S43000 |

| 11 | 1.4510 | 439 | SUS439 | S43932 |

| Thnique | Surface Finsh | Grade | Thickness(mm) | Width(mm) | |

| 8.0 - 600 | |||||

| Hot Rolled | No.1 | 201/304/304L/316L/430 | 2.50-10.00 | √ | √ |

| Cold Rolled | 2B | 201/202/304/304L/316L/430/420J2/439 | 0.26-3.00 | √ | √ |

| BA | 201/304/410S/430 | 0.30-2.00 | √ | √ | |

| No.4 | 201/202/304/304L/316L/410S/430/420J2/439/ | 0.30-3.0 | √ | √ | |

| HL | 201/202/304/304L/316L/410S/430/420J2/439 | 0.26-2.50 | √ | √ | |

| 8K(Mirror) | 201/202/304/304L/316L/410S/430/420J2/439 | 0.26-2.50 | √ | √ | |

| Polishing | 201/202/304/304L/316L/430/420J2/439 | 0.30-2.00 | √ | √ | |

| GRADE | NI | CR | CU | MN | SI | C | N | P | S | MO | AI | NB | TI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 201 | 0.80-1.30 | 14.00-17.00 | 1.30-2.00 | 8.00-10.00 | <1.00 | <0.15 | <0.25 | <0.06 | <0.03 | / | / | / | / |

| 202 | 3.50-5.50 | 17.00-18.00 | 1.30-1.80 | 5.50-7.50 | <1.00 | <0.15 | 0.05-0.25 | <0.045 | <0.015 | / | / | / | / |

| 304 | 8.00-12.00 | 17.50-19.50 | / | <2.00 | <0.75 | <0.03 | / | <0.045 | <0.03 | / | / | / | / |

| 304L | 8.00-12.00 | 17.50-19.50 | / | <2.00 | <0.75 | <0.03 | / | <0.045 | <0.03 | / | / | / | / |

| 316L | 10.00-14.00 | 16.00-18.00 | / | <2.00 | <0.75 | <0.03 | <0.10 | <0.045 | <0.03 | 2.00-3.00 | / | / | / |

| 321 | 9.00-12.00 | 17.00-19.00 | / | <2.00 | <2.00 | <0.08 | <0.10 | <0.045 | <0.03 | / | / | / | 5(C+N)-0.7 |

| 409L | <0.50 | 10.5-11.7 | / | <1.00 | <1.00 | <0.03 | <0.03 | <0.040 | <0.03 | / | / | <0.17 | 6xC-0.75 |

| 410S | <0.60 | 11.50-13.50 | / | <1.00 | <1.00 | <0.08 | / | <0.040 | <0.03 | / | / | / | / |

| 420J2 | <0.60 | 12.00-14.00 | / | <1.00 | <1.00 | 0.26-0.40 | / | <0.040 | <0.03 | / | / | / | 6xC-0.75 |

| 430 | <0.60 | 16.00-18.00 | / | <1.00 | <0.75 | <0.12 | / | <0.040 | <0.030 | / | / | / | / |

| 439 | <0.50 | 17.00-19.00 | / | <1.00 | <1.00 | <0.03 | <0.03 | <0.040 | <0.030 | / | 0.15 | <0.17 | / |

| GRADE | Y.S. | T.S. | ELOG. | HRB |

|---|---|---|---|---|

| 201 | ≥310 | ≥665 | ≥35 | ≥105 |

| 202 | ≥260 | ≥620 | ≥40 | ≥100 |

| 304 | ≥205 | ≥520 | ≥40 | ≥90 |

| 304L | ≥205 | ≥520 | ≥40 | ≥90 |

| 316L | ≥170 | ≥480 | ≥40 | ≥95 |

| 321 | ≥205 | ≥520 | ≥40 | ≥90 |

| 409L | ≥175 | ≥360 | ≥25 | ≥80 |

| 410S | ≥205 | ≥410 | ≥20 | ≥88 |

| 420J2 | ≥225 | ≥540 | ≥18 | ≥99 |

| 430 | ≥205 | ≥450 | ≥22 | ≥88 |

| 439 | ≥205 | ≥415 | ≥22 | ≥89 |

Our stainless steel strip applications are everywhere

Stainless steel is used in all aspects of architecture and building, such as curtain wall and roofing. Some are used as masonry and stone anchors, bollards and safety railings.

Stainless steel has durable properties that make it an excellent choice for kitchen and sanitary products such as kitchen sinks, faucets, bottles, knives, sanitary valves and pipes.

Stainless steel are widely used in interior and exterior decorations such as ceilings, screens, furniture and outdoor areas due to its positive features.

Grade 304, 316L, 410, 420 stainless steel are widely used in medical tools, such as medical carts and trays, cabinets and surfaces, wheelchairs, and surgical tools. (scalpels, scissors, clamps, etc.)

Stainless steels are widely used in food and beverage manufacturing and processing industries for manufacture, bulk storage and transportation, preparation and presentation applications.

Chemical process equipment, piping systems and instrumentation all make extensive use of austenitic stainless steel materials of construction. Most commonly used are Grade 304L and 316L.

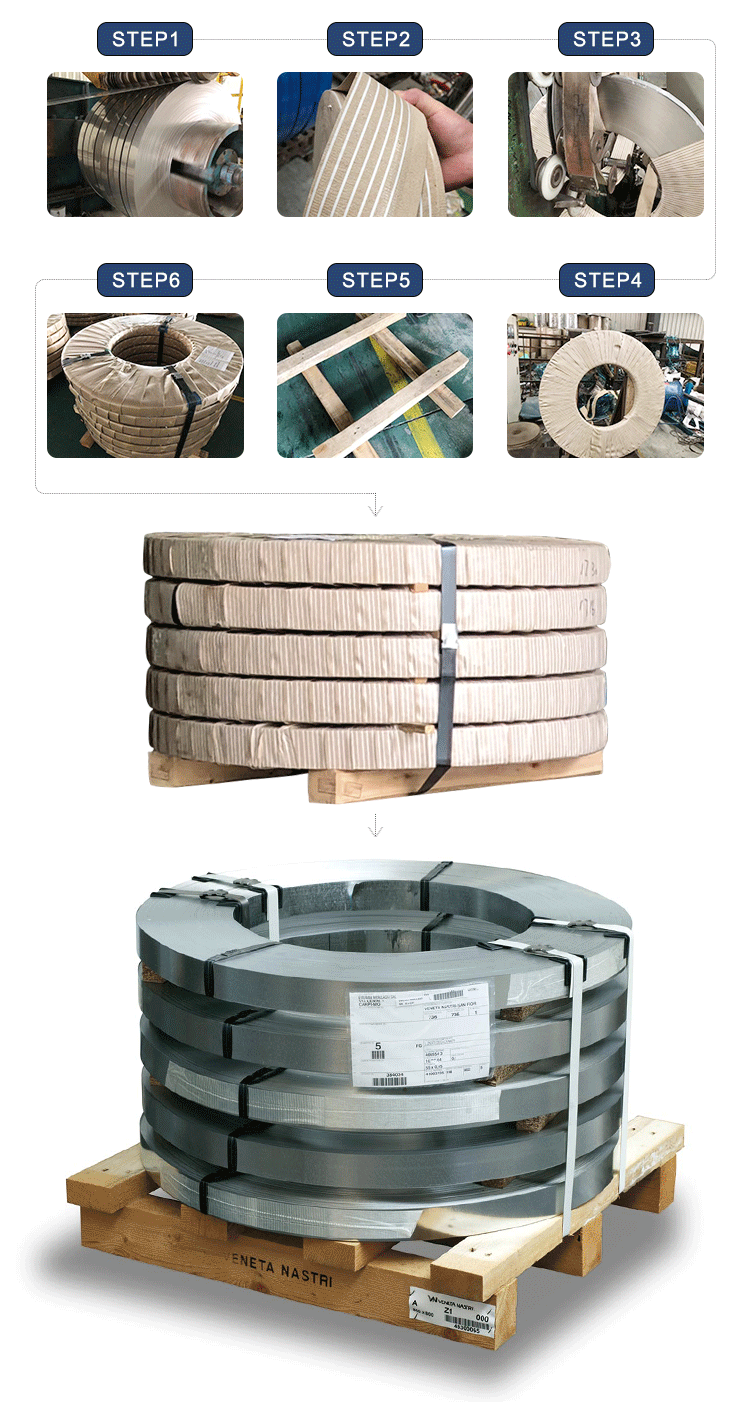

The detailed of stainless steel strip quality control procedures are as follows:

1. Incoming inspection of master coils (MTC verification, visual checks).

2. Slit by specialists with precision equipment ensures consistent width, edge quality, and minimal burrs.

3. In-process checks (width, camber, edge condition, surface defects).

4. Final inspection before packaging.

We are the core agent for steel mills such as TSINGSHAN, TISCO, BAO STEEL, POSCO, and JISCO, and our stainless steel grades include: 200 series,300 series, and 400 series etc.

Standard stock products can be shipped within a few days. Custom orders (depending on the material grade, complexity of the surface treatment, and required slitting widths and tolerances) may take weeks or even months.

We are able to cover all types of surfaces and sizes of stainless steel strip, specializing in customized service. The standard width size of stainless steel strip can be 8mm to 100mm,and the customized width can be up to 1500mm.

Our company has a strong after-sales team, and each order is matched with dedicated production staff to follow up.The processing progress of the order is synchronized to the sales staff in real time every day. Each order must go through multiple inspection procedures before shipment to ensure Delivery is possible only if delivery requirements are met.

We are pleased to offer a limited amount of free samples to all authorized professional clients according to their specific demands.

By continuing to use the site you agree to our privacy policy Terms and Conditions.