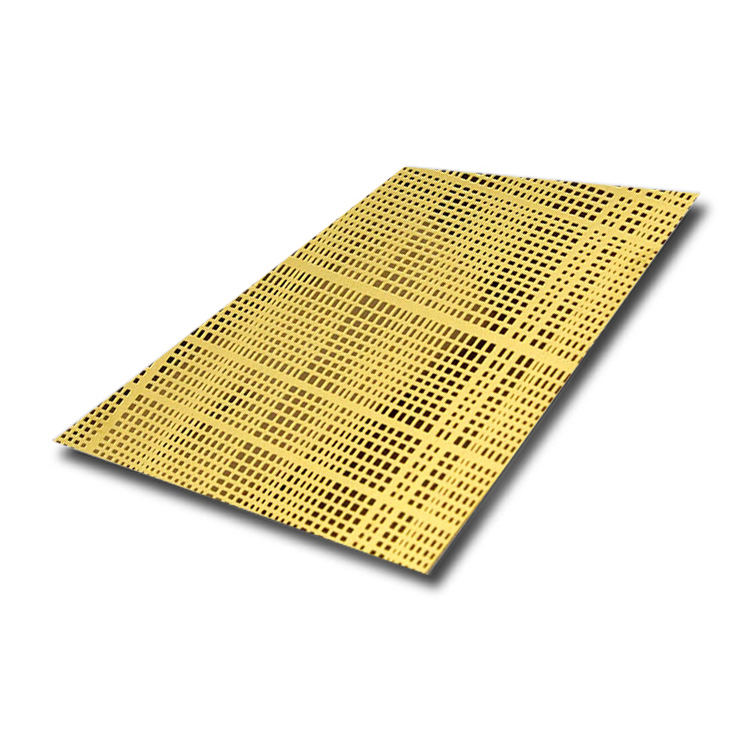

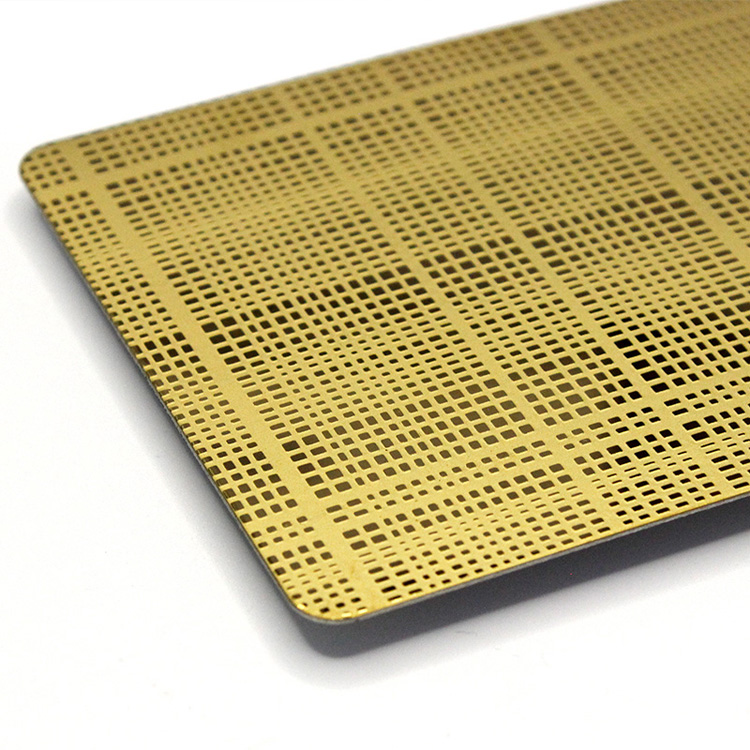

This mirror gold etched stainless steel sheet with small cube pattern adopts the etching process, and the small cube pattern is etched on the surface of the mirror gold stainless steel sheet through chemical etching technology, thus forming a beautiful decorative stainless steel sheet.

|

Brand:

|

|

|

Place Of Origin:

|

|

|

Payment Terms:

|

|

|

Delivery Time:

|

|

|

Package Detail :

|

|

|

Price Term:

|

|

|

Sample:

|

|

Description of Miror Gold Etched SS Sheet With Small Cube Pattern

This mirror gold etched stainless steel sheet with small cube pattern adopts the etching process, and the small cube pattern is etched on the surface of the mirror gold stainless steel sheet through chemical etching technology, thus forming a beautiful decorative stainless steel sheet.

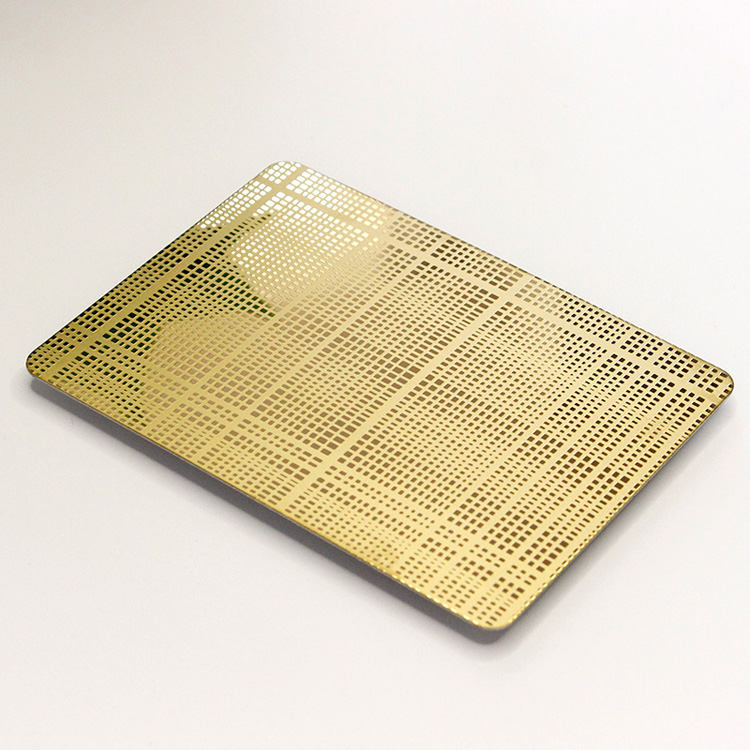

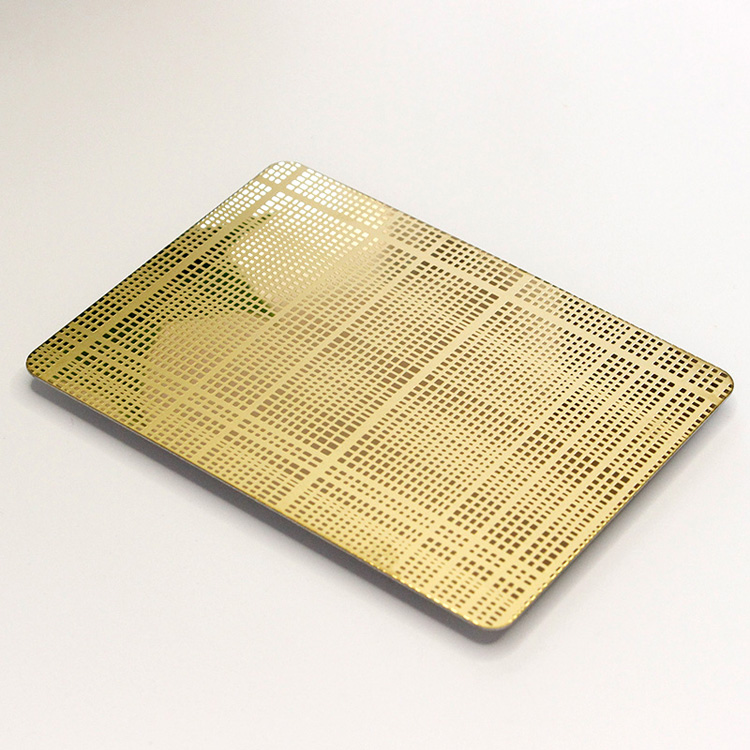

This type of etched stainless steel sheet is usually used for wall decoration, especially for elevator door panels and elevator cars, and is very popular among elevator designers.

|

Item |

Modern Popular Small Cube Pattern 304 316 Grade Mirror Etched Stainless Steel Decorative Sheet In PVD Titanium Gold Color Coating |

| Standard | ASTM, AISI, DIN, EN, GB, JIS |

|

Brand Name |

Grand Metal |

|

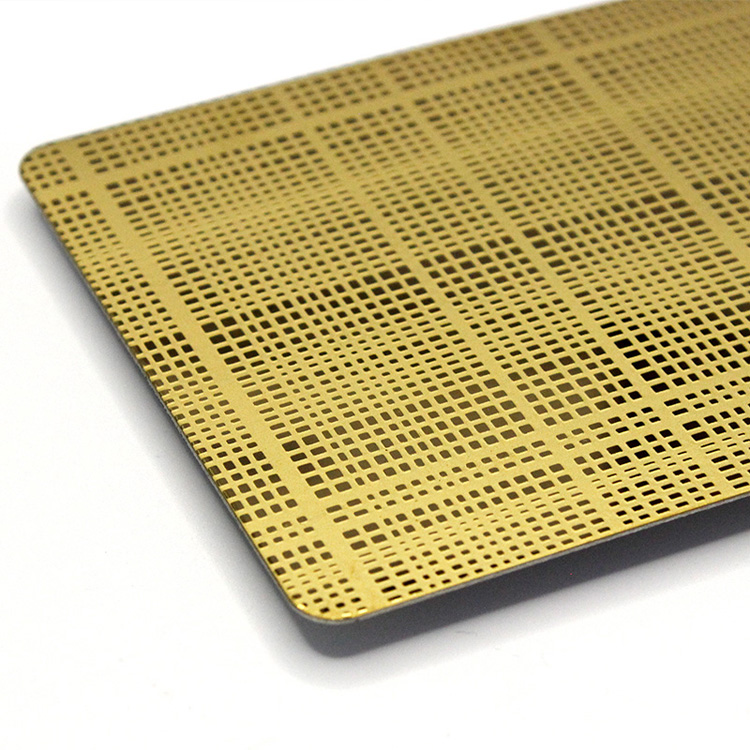

Surface Finish |

Etched+Mirror+PVD Color Coating |

|

Type |

Sheet |

|

Grade |

304 316 |

|

Material |

Stainless Steel |

|

Thickness(mm) |

0.3-3mm |

|

Width(mm) |

1000/1219/1220/1240/1250/1500/Customized |

| Color | Titanium Gold |

| Pattern | Small Cube |

| Application | Elevator Cabin Decoration |

Product display

Product details

The process of etched stainless steel sheet

For more process introduction of etching stainless steel plate, please click the picture

More patterns of etched stainless steel sheet for you to choose

The features of etched stainless steel sheet

1. Corrosion resistance

2. High hardness

3. Good processability

4. Various surface effects

5. Long life

6. Environmental protection

The advantage of stainless steel etching process

The stainless steel etching process is a process technology that uses chemical corrosion to etch patterns or characters onto the surface of stainless steel. It has the following 5 major advantages:

High precision:

Stainless steel etching can be achieved with a very high level of precision and detail, enabling precise patterns, logos or writing to be etched into stainless steel surfaces. This makes it useful in applications that require high-precision lettering or marking, such as engraving artwork, instrumentation, electronics, and more.

Durability:

Stainless steel itself has good corrosion resistance and wear resistance, so etched patterns or characters can remain clear and durable for a long time on the stainless steel surface. This makes stainless steel etching very practical in applications that require long-term use and resistance to wear, such as outdoor signage, industrial equipment, and more.

Diversity:

Stainless steel etching can create a variety of different patterns and effects, such as relief effects, yin and yang engraving effects, yin and yang conversion effects, etc. This variety makes stainless steel etching a wide range of applications in the field of design and decoration, which can achieve personalized and unique effects.

Environmental protection:

Compared to other processing methods, stainless steel etching usually uses chemical etching methods without requiring extensive mechanical processing or generating large amounts of waste. This gives it certain advantages in terms of environmental protection, which can reduce the impact on the environment.

Productivity:

Stainless steel etching can be performed in an automated and computer-controlled manner, increasing productivity and consistency. This makes stainless steel etching ideal for high-volume production needs and high-efficiency production environments.

Why choose our etched stainless steel made from Grand Metal Manufacturer?

1.Consistent Quality.

All our facilities are tested several times before production, and each product will be prototyped before bulk production to ensure stable quality.

2.Moderate Price.

We know the profitability is the primary goal of our valued customers. Our work is not only to bring excellent products, save your costs is also very important.

3.Strong Customization.

With our proactive team of talented designers, experienced engineers, and full range of processing lines, 90% of your special needs could be resolved here.

Application of Miror Gold Etched SS Sheet With Small Cube Pattern

This type of mirror gold etched stainless steel sheet with samll cube pattern is usually used for wall decoration, especially for elevator door panels and elevator cars, and is very popular among elevator designers.

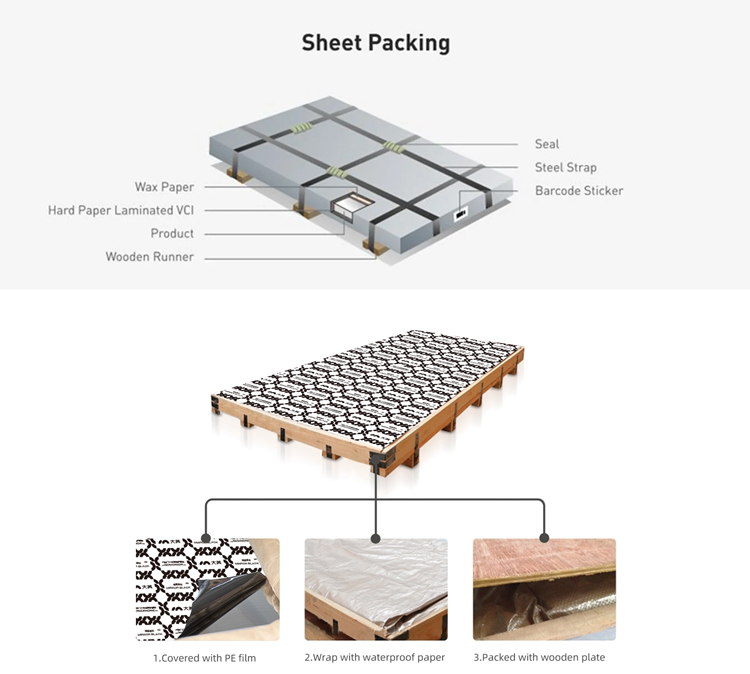

Packaging details

|

Protective Film |

1. Double layer or single layer. 2. Black and white PE film/Laser (POLI) film. |

|

Packing Details |

1. Wrap with waterproof paper. 2. Cardboard encase all packs of the sheet. 3. The strap aligned with edge protection. |

|

Packing Case |

Strong wooden case, metal pallet and customized pallet are acceptable. |

Q1:What are Grand Metal's products?

A1:Grand Metal's mainly products include 200/300/400series stainless steel coils/ sheets/tiling trims/strips/circles with all different styles of etched, embossed, mirror polishing, brushed and PVD color coating etc.

Q2:How can you ensure the quality of your product?

A2:All products have to go through three checks in the whole manufacturing process, which include production, cutting and packing.

Q3:What is your delivery time and the supply ability?

A3:The delivery time normally within 15~20 working day and we can supply about 15,000 tons every month.

Q4:About the complaint, quality problem, after-sales service etc,how do you handle it?

A4:We will have certain colleagues to follow our orders accordingly. Each order is equipped with professional after-sales service. If any claim happened, we will take our responsibility and compensate as per contract. To better serve our clients, we'll keep trace feedback of our products from clients and that's what makes us different from other suppliers. We're customer care enterprise.

Q5:What is the MOQ?

A5:We don't have MOQ. We treat every order with heart. If you are scheduling to place a trial order, pls feel free to contact us and we can meet your requirements.

Q6:Can you provide OEM or ODM service?

A6:Yes, we have a strong developing team. The products can be made according to your request.

Q7:How to clean and maintain its surface?

A7:Use neutral cleanser and soft cotton cloth. Do not use acid cleanser and rough material.

If you are interested in our products and would like to know more details,please leave a message here,we will reply you as soon as we can.

If you want to know more product information, or the latest quotation, you can contact us at any time, we will do our best to provide more services.

By continuing to use the site you agree to our privacy policy Terms and Conditions.