Embossed stainless steel sheet is a specially treated stainless steel sheet, which is processed with embossing or pattern on the surface by mechanical or chemical methods, so that it has decorative and anti-skid functions. Embossed stainless steel sheets are usually made of stainless steel, such as 304, 316 grade stainless steel, to ensure its corrosion resistance and durability.

The processing of embossed stainless steel sheet can be carried out by methods such as mechanical pressure, rolling or laser etching. Three-dimensional patterns, patterns or textures will be formed on the surface of the processed stainless steel plate, and the common ones are wave pattern, ear pattern, square pattern and so on. These patterns can not only provide decorative effects, but also increase the strength and anti-slip performance of the board, which are suitable for indoor and outdoor architectural decoration, furniture manufacturing, elevators, floors, walls and other fields.

Regarding the process flow of stainless steel embossed sheet it specifically includes the following steps:

Material preparation:

Select applicable stainless steel materials, common ones include 304, 316 grade stainless steel. Select the thickness and specification of the material according to the design requirements and application scenarios.

Pattern design:

According to customer needs or designer's requirements, carry out pattern design, or choose an existing pattern, and use computer-aided design (CAD) software to draw or modify the pattern.

Surface preparation:

Stainless steel sheets require surface preparation prior to embossing to ensure they are clean and flat. Process steps such as degreasing, pickling, and rinsing are usually used to remove impurities and oxides.

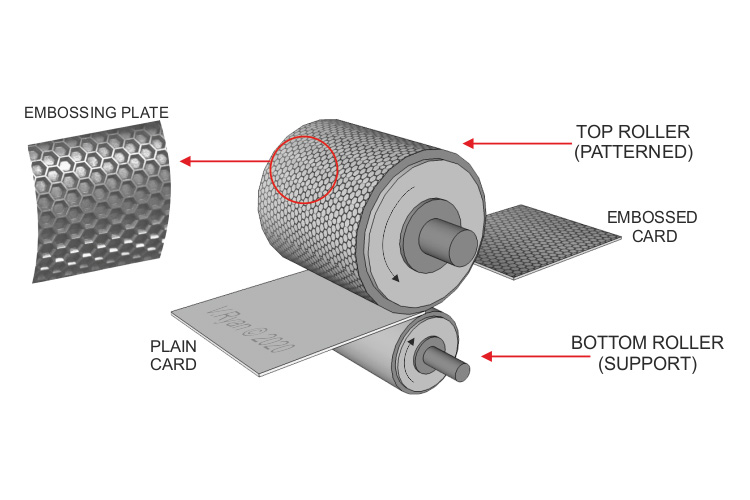

Embossing machine processing:

The surface-treated stainless steel plate is sent to the embossing machine for processing. Embossing machines use mechanical pressure or rolling to apply pressure to the surface of stainless steel sheets to create patterns, textures or patterns. The embossing machine has different dies and rollers, which can be adjusted according to the needs.

Fine processing:

After the preliminary embossing is completed, some fine processing may be required, such as removing edge burrs, trimming the size of the stainless steel plate, etc.

Cleaning and polishing:

After embossing and fine processing, the stainless steel plate needs to be cleaned and polished to remove the dirt and blemishes left during the processing and make the surface smoother and more beautiful.

Inspection and packaging:

inspect the embossed stainless steel plate to ensure its quality meets the requirements. It is then packaged to prevent damage during shipping and storage.

For more introduction of stainless steel embossing process, please pay attention to: www.grandstainless.com

By continuing to use the site you agree to our privacy policy Terms and Conditions.