We all know that medical-grade stainless steel must have certain antibacterial properties, corrosion resistance, high temperature resistance and mechanical properties to meet the production requirements of medical equipment and instruments.Then, the only stainless steel type that can meet such requirements at the same time is 316L.

316L stainless steel is a low-carbon chromium-nickel-molybdenum stainless steel, which is a type of stainless steel material and is a variant developed from the common stainless steel 316 stainless steel.Its "L" stands for Low Carbon, and its carbon content is low, usually below 0.03%.

The chemical elements of 316L stainless steel are mainly composed of chromium, nickel, molybdenum and a small amount of carbon, silicon, manganese, phosphorus and sulfur.Its chemical composition content is mainly as follows:

1. Chromium (Cr): 16%~18%

2. Nickel (Ni): 10%~14%

3. Molybdenum (Mo): 2%~3%

4. Carbon (C): <0.03%

5. Silicon (Si): ≤ 1.0%

6. Manganese (Mn): ≤ 2.0%

7. Phosphorus (P): ≤ 0.045%

8. Sulfur (S): ≤ 0.03%

9. Nitrogen (N): ≤ 0.1%

10. Iron (Fe): Balance

316L stainless steel material complies with relevant international biocompatibility standards and is harmless to human tissues and will not cause allergic reactions or other adverse effects.

316L stainless steel has good corrosion resistance and can resist corrosion caused by physiological fluids, drugs, cleaning and disinfectants, etc.Especially in medical environments, it can resist the erosion of corrosive media such as chloride.

316L stainless steel has good high temperature resistance and will not cause problems such as deformation, delamination or oxidation due to high temperatures, thus allowing medical equipment or instruments to be disinfected or sterilized under high temperature conditions.

316L stainless steel material has sufficient strength, hardness and toughness to ensure the stability and safety of medical equipment and instruments.

The surface of 316L stainless steel is smooth, not easy to breed bacteria, and easy to clean to meet the needs of cleaning and disinfection of medical instruments and equipment.

316L stainless steel is widely used in the medical industry due to its excellent antibacterial properties, corrosion resistance, biocompatibility and mechanical properties.The specific usage scenarios are as follows:

316L stainless steel has good biocompatibility and corrosion resistance and is often used to manufacture medical devices, such as surgical instruments (scalpels, tweezers, etc.), oral medical devices (dental surgical instruments, braces, etc.) and various implants Type medical devices (bone nails, artificial joints, etc.).

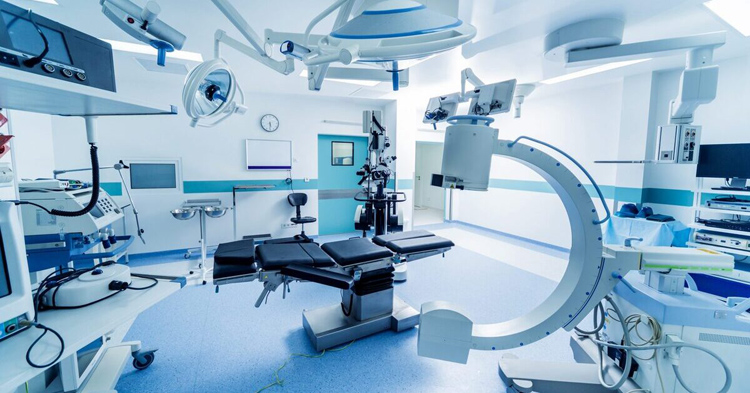

316L stainless steel is widely used in the manufacture of medical equipment, such as operating room equipment (operating tables, operating lights), imaging diagnostic equipment (X-ray machines, nuclear magnetic resonance machines), laboratory equipment (laboratory tables, experimental instruments, etc.) and various A variety of treatment equipment (electric knife, laser therapy instrument, etc.).

316L stainless steel is also widely used in the field of biomedicine, such as pharmaceutical equipment (reactors, centrifuges), bioreactors, biomaterial processing equipment, etc.

316L stainless steel is also used to manufacture various medical consumables, such as operating room sterilization equipment, syringes, infusion sets, catheters, etc.

In summary, 316L stainless steel combines its low carbon content with excellent antibacterial and high temperature resistance properties and can meet the strict requirements of biocompatibility and corrosion resistance of medical devices. There is no doubt that it has become the preferred material for the medical industry.

By continuing to use the site you agree to our privacy policy Terms and Conditions.