The cutting process of stainless steel coil to plate requires the use of a cutting machine. The coil cutting machines allow to cut on raw material, optimizing its use: thanks to the nesting of the figures on coils without a length limit, we can produce a higher number of pieces than if we were working with previously cut stainless steel sheets, reducing waste by 20-30%. Less waste and more pieces produced: with the same surface area, the coil nesting allows to make better use of the raw material available.

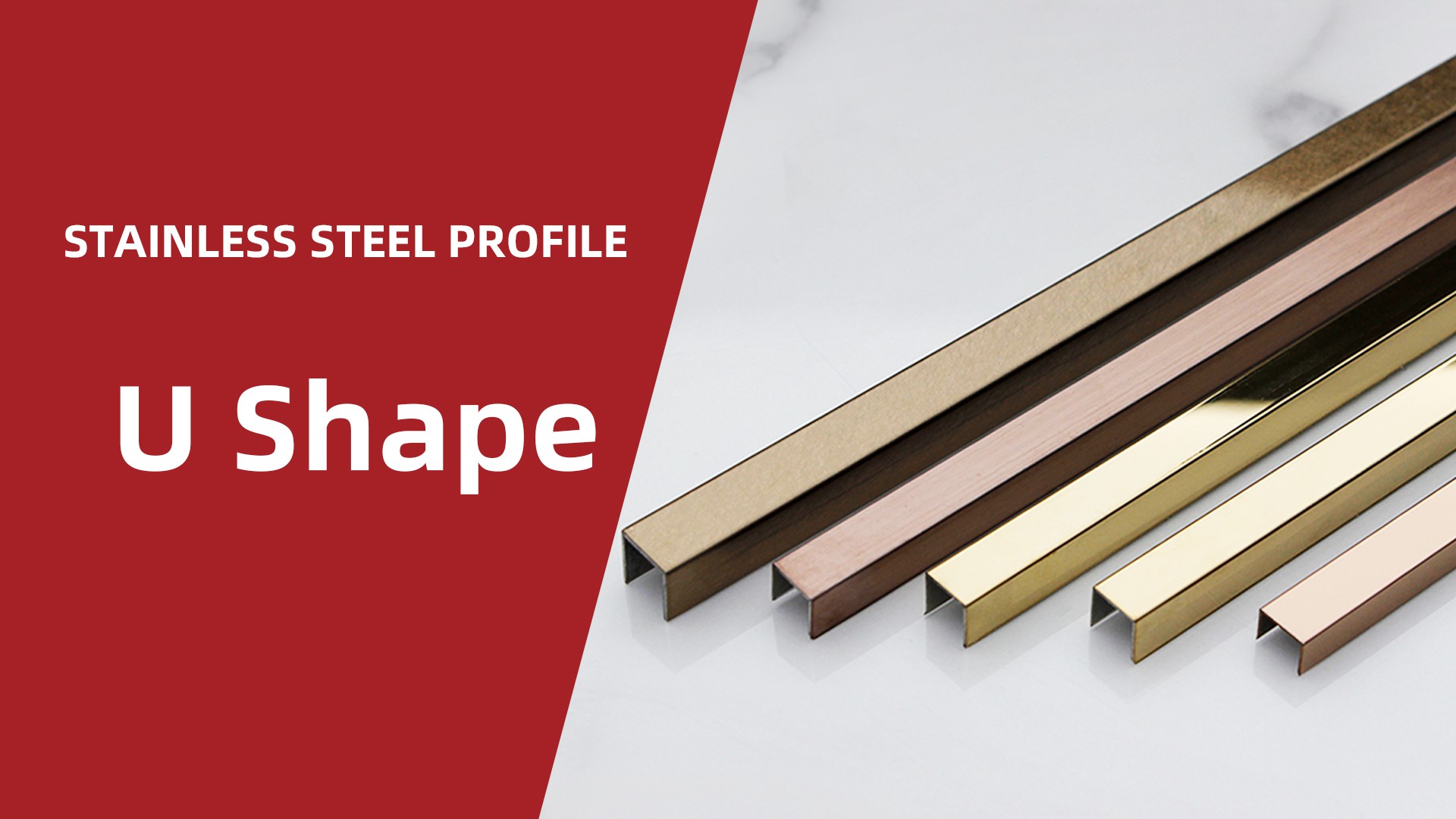

Stainless Steel U Profile Sections are made by CNC Bending.Before Bending, these Sheets are cut to their required sizes by Laser Cutting Machines. Our Stainless Steel U Profiles Grooving is done on Metal Sheets before bending them. By following this process, we can achieve a 90° right angle on the bend area.

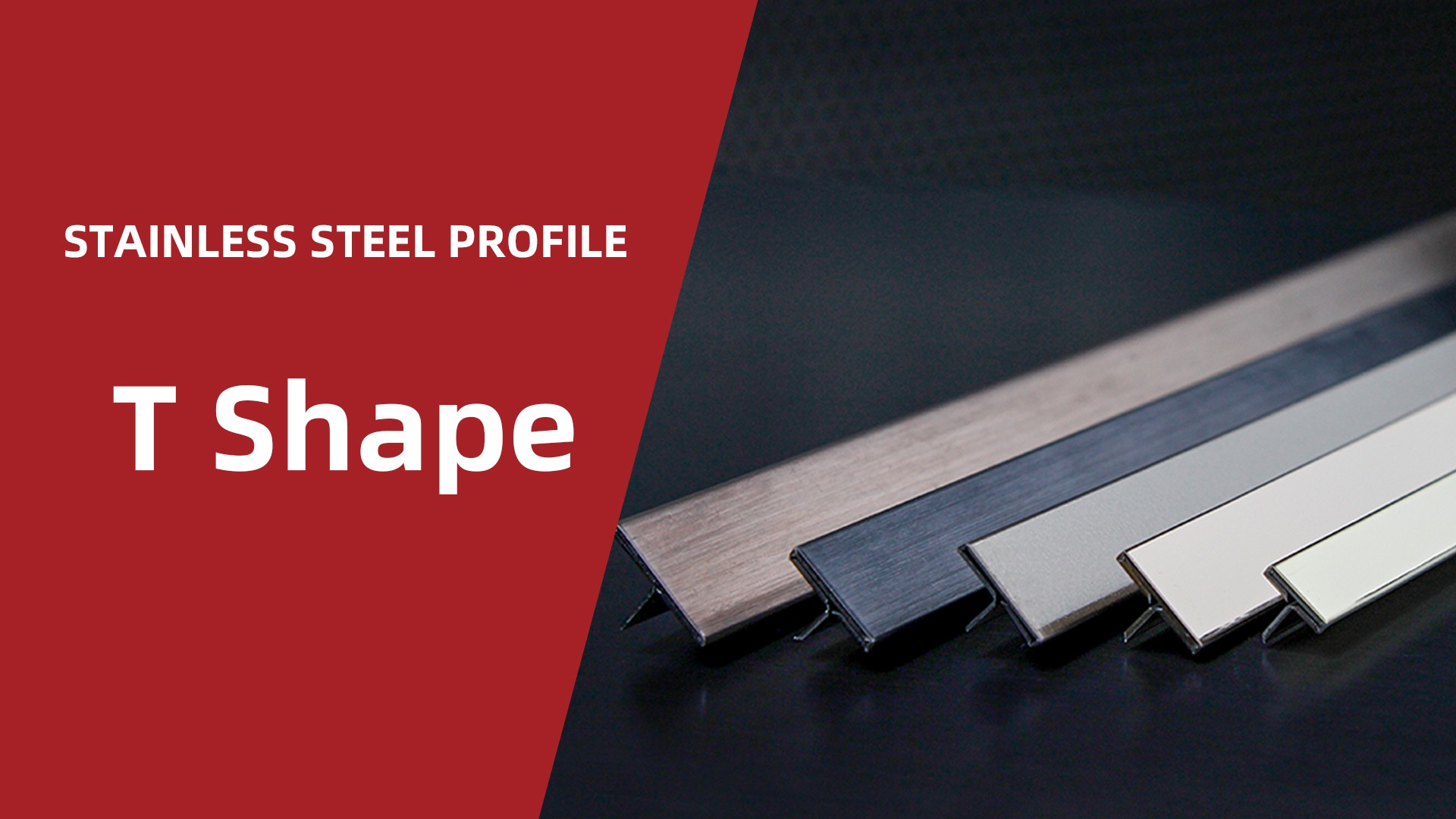

T shape stainless steel tile trim is designed for transitions between hard surface floor coverings that are the same-height. It can be used to retrofit an existing installation or can be installed during the tile installation. It overlaps the edges of the floor coverings to protect the edges against damage. Installation is quick and easy by filling the joint between the floor coverings with an elastomeric sealant, and pressing the profile into the joint. Stainless Steel Straight Edge Tile Trim is a straight edge tile trim profile for the protection and neat finishing of tiled corners and edges. Features a perforated anchoring leg for securing in the adhesive or mortar bed below the tiled surface.

The basic plates of Mirror 8k stainless steel are mostly 2B and BA. it is necessary to mix the grinding liquid during the product process: mix water, nitrate acid, iron-red powder, etc. according to a certain ratio to make a grinding liquid. Moreover, the better the ratio is deployed, the higher the quality of the product First step – Rough polishing Second step – Fine polishing Third step – Washing and drying Fourth step – Quality inspection The final step – Packing with protective film

Stainless Steel L Profile Sections are made by CNC Bending. Before Bending, these Sheets are cut to their required sizes by Laser Cutting Machines. Our Stainless Steel L Profile Section Grooving is done on Metal Sheets before bending them. By following this process, we can achieve a 90° right angle on the bend area.

By continuing to use the site you agree to our privacy policy Terms and Conditions.