What is stainless steel anti-scratch process?

The stainless steel anti-scratch process is a surface treatment technology designed to enhance the scratch resistance of stainless steel sheets while giving them an aesthetically pleasing surface effect. Through this process, a certain texture or pattern can be formed on the surface of the stainless steel, making it difficult to be scratched, and at the same time increasing the decorativeness of the product.

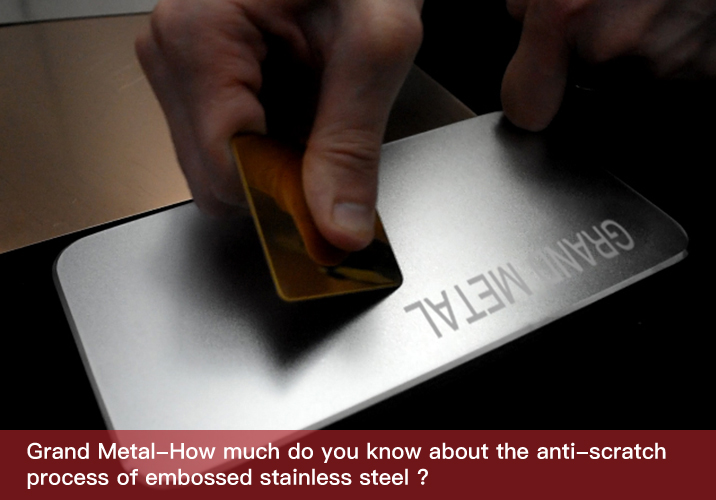

Now,Let us compare the difference between the anti-scratch function and the stainless steel sheet without anti-scratch function, as follows:

Non Anti-scratch stainless steel sheet:

With Anti-scratch stainless steel sheet:

What types of steel are suitable for the stainless steel anti-scratch process?

The Stainless Steel Scratch Resistant process is suitable for most types of stainless steel, including:

1. Austenitic (austenitic) stainless steel:

such as common 304, 316 and other stainless steels, these steels perform well in the anti-scratch process.

2. Ferritic (ferritic) stainless steel:

such as 430 stainless steel, can also use anti-scratch technology.

3. Duplex (duplex) stainless steel:

such as 2205, etc., this type of stainless steel is usually also suitable for scratch-resistant technology.

4. Martensitic stainless steel:

such as 410 stainless steel, can also use anti-scratch technology.

What are the processed stainless steel plates suitable for the stainless steel anti-scratch process?

1. Cold-rolled stainless steel sheet:

Cold-rolled stainless steel sheet is processed by rolling stainless steel coils through a cold rolling mill at room temperature. The surface is relatively smooth and suitable for anti-scratch treatment.

2. Polished stainless steel sheet:

Polishing is a processing method that grinds and polishes the surface of stainless steel sheet to obtain a smooth and mirror effect. This surface treatment is suitable for anti-scratch process.

3. Sandblasted stainless steel sheet:

Sandblasted is to make the surface of stainless steel produce texture effect by brushing and grinding. The processed stainless steel sheet can also be treated with anti-scratch process.

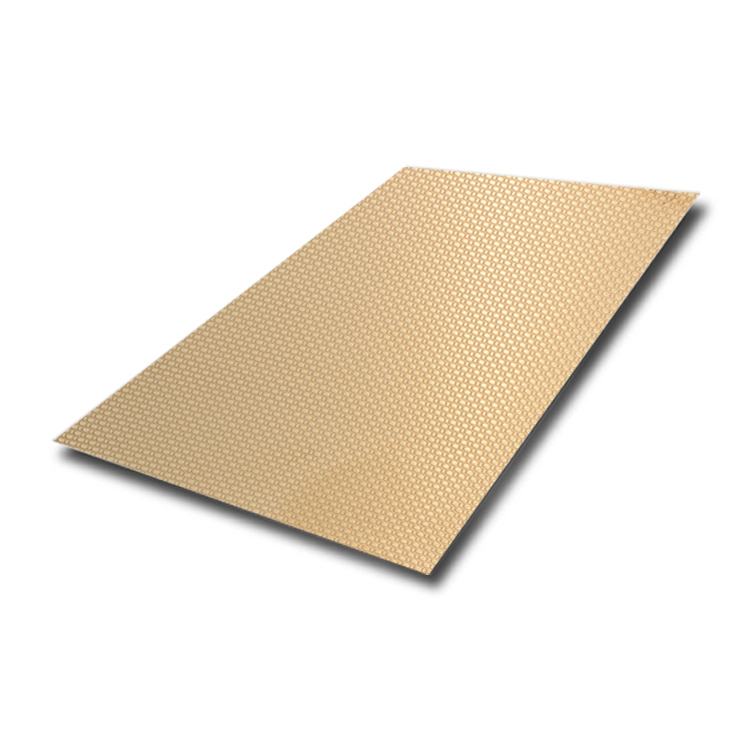

4. Titanium-plated stainless steel sheet:

A layer of titanium is plated on the surface of stainless steel to form a metallic color effect. This titanium-plated stainless steel sheet can also be applied to the anti-scratch process.

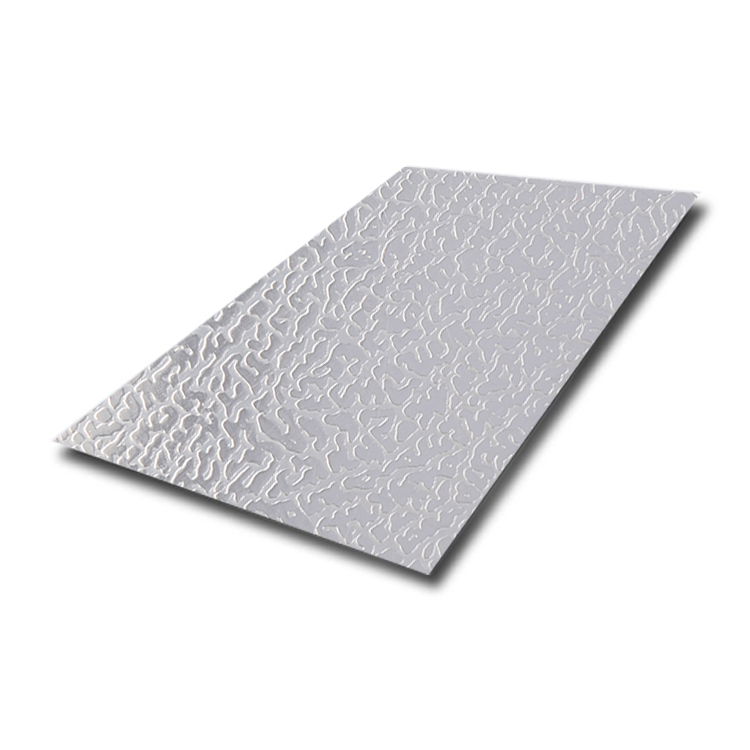

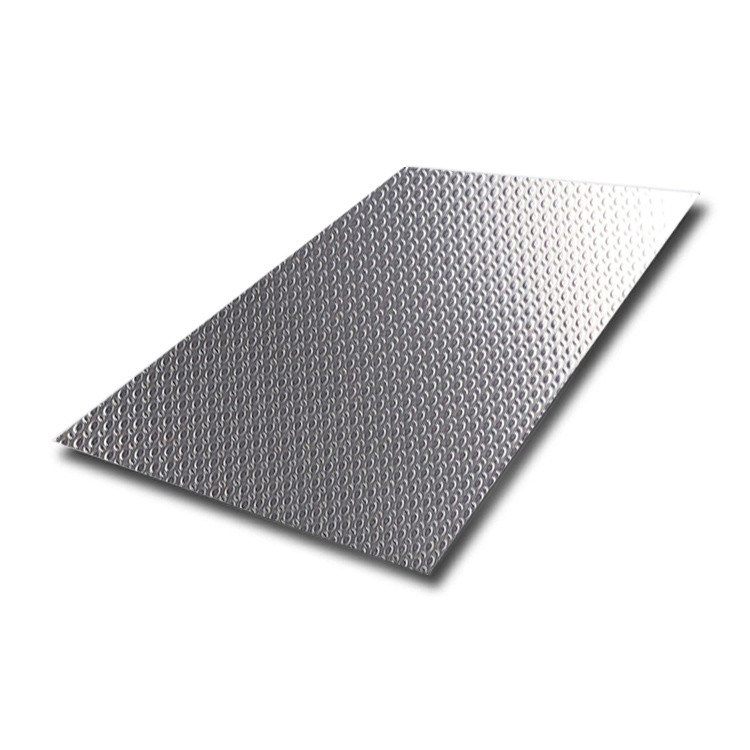

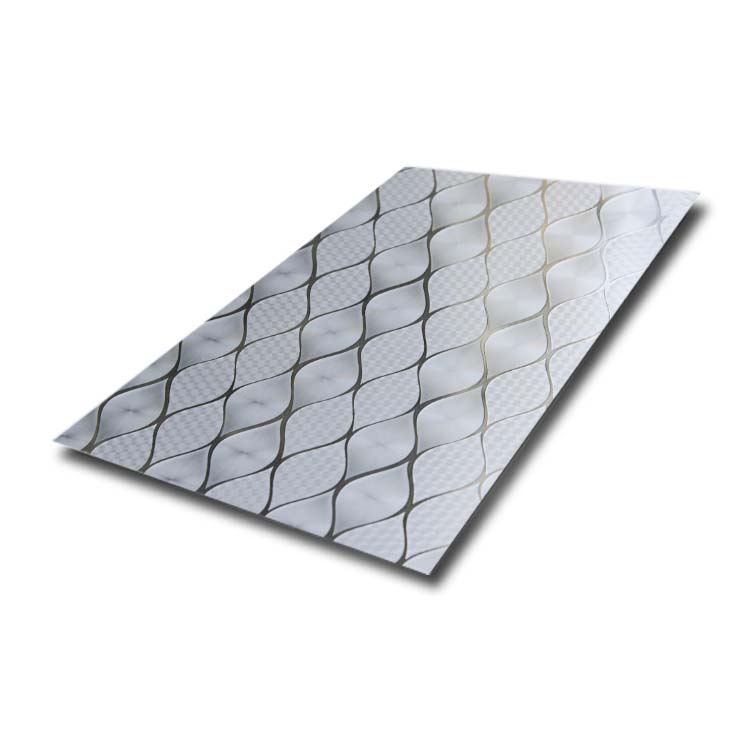

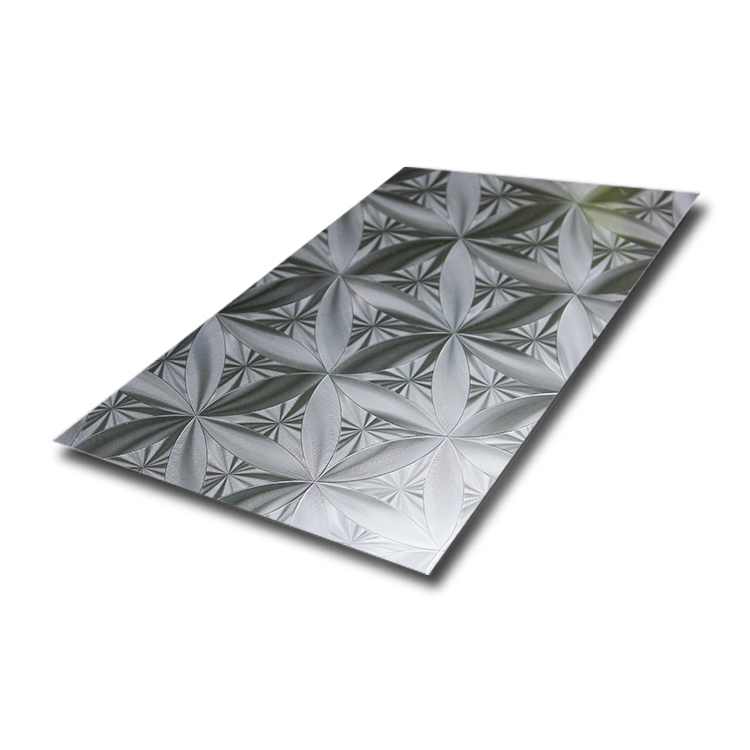

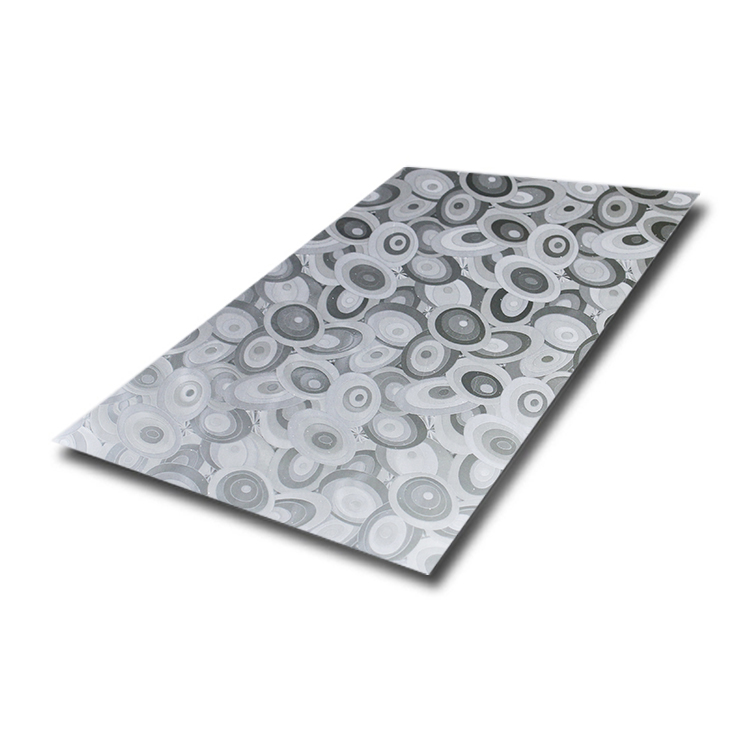

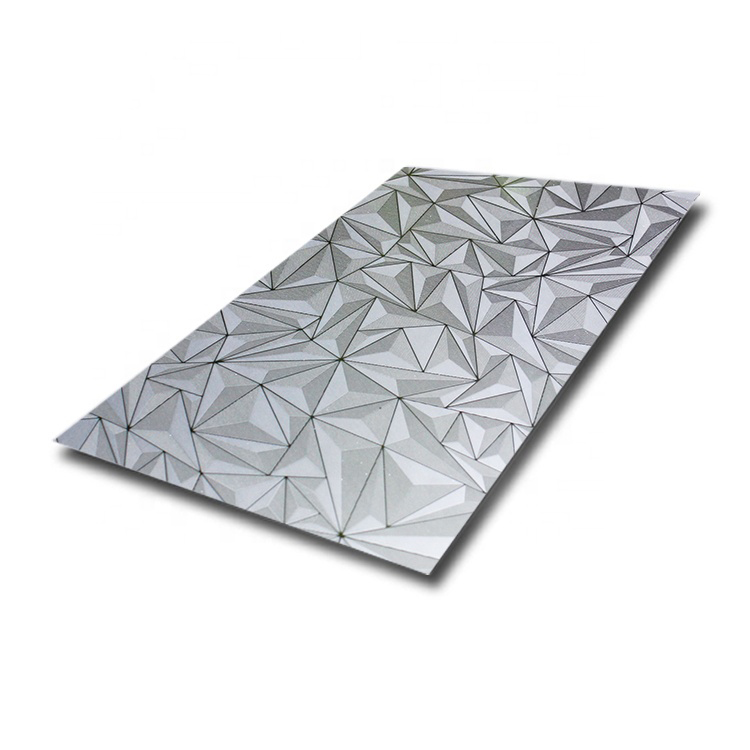

5. Embossed stainless steel sheet:

Emboss the stainless steel sheet through the mold to produce various patterns and patterns on the surface. The embossed stainless steel sheet is also suitable for anti-scratch process.

In this regard, any processed stainless steel plate with a relatively flat surface without too many protrusions and unevenness can consider using an anti-scratch process to improve its scratch resistance. However, for special stainless steel plate processing methods or products with complex surface structures, it may be necessary to evaluate the applicability of the anti-scratch process according to the actual situation.

In general, stainless steel sheets suitable for use with scratch-resistant technology need to meet the following conditions:

1. Higher surface quality requirements:

Anti-scratch technology is mainly used to improve the scratch resistance and aesthetics of stainless steel plates, so the requirements for surface quality are higher. Generally, only stainless steel plates with a relatively smooth surface and a good finish are suitable for anti-scratch treatment.

2. Material requirements:

The anti-scratch process is suitable for most types of stainless steel plates, including Austenitic, Ferritic, Duplex and Martensitic stainless steel. However, special alloys or stainless steels with complex structures may not be suitable for this process.

3. Processing technology requirements:

Generally, stainless steel plates processed by cold rolling, polishing, sand brushing, embossing, etc. are more suitable for anti-scratch treatment. These processing techniques can make the surface of stainless steel relatively flat and the surface texture more consistent, which is conducive to the process.

4. No important functional requirements on the surface:

the anti-scratch process will form a certain texture or pattern on the stainless steel surface, so it is suitable for products that do not need to be completely flat or have no other special functional requirements.

5. Appropriate process equipment:

The anti-scratch process requires corresponding equipment and process flow, including scraping or grinding tools, and appropriate process control to ensure the stability and consistency of the process effect.

6. Process cost and effect evaluation:

Before applying the anti-scratch process, it is necessary to conduct cost and effect evaluation to ensure that the cost of the process is controllable and can meet the expected surface effect.

For more information about stainless steel scratch-resistant technology, please pay attention to: www.grandstainless.com

Decorative Stainless Steel Sheet

Decorative Stainless Steel Sheet